- 623 Grable St. Rockford, IL 61109

- jason@a1lapping.com

- 815-398-1465

Since it’s inception in 1975 the focus of A-1 Lapping has been, continues to be, and always will be quality. We believe that the quality of the products that we provide is the single most important aspect of our business. We are constantly striving to continuously improve upon our already excellent quality record. Through continuous investment our inspection capabilities are second to none. The level to which we can inspect critical dimensions gives our customers the peace of mind to know that their parts are right, every time. It’s the reason we’re able to serve over 175 customers throughout the world across the Aerospace, Automotive, Heavy Equipment, Hydraulic, Medical, and Oil/Gas industries, to name a few. Be sure to check out some of our case studies below.

(Click any part name for full specs and details.)

Machine: Stahli 1205

Wheel: D76

Stock Removal: .020"

Parts Per Load: 72

Cycle Time: 3 mins

Rinsing Agent: Oil

Material: Powdered Metal

Previous Operation: None

Part Dimension: 3.5" O.D.

Tolerance: .004"

Cpk Achieved: 12+

Ra Achieved: 10

Flatness Achieved: <.000075"

Parallelism Achieved: .00008"

Comments

Previous operation rough grind then lap, now achievable in one step process.

Machine: Stahli 705

Wheel: D76

Stock Removal: .025"

Parts Per Load: 48

Cycle Time: 3 mins

Rinsing Agent: Oil

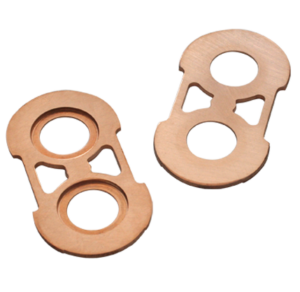

Material: Bronze

Previous Operation: Stamped

Part Dimension: 1" X 2"

Tolerance: .0002"

Cpk Achieved: 1.67

Ra Achieved: 20

Flatness Achieved: <.001"

Parallelism Achieved: .00005"

Comments

Out of flat up to .010" incoming, finished at .0625" thick

Machine: Stahli 705

Wheel: B76

Stock Removal: .008"

Parts Per Load: 588

Cycle Time: 3 mins

Rinsing Agent: Oil

Material: 1045 H.T. to 55 Rc

Previous Operation: Turned

Part Dimension: .500" O.D.

Tolerance: .0005"

Cpk Achieved: 1.67

Ra Achieved: 10

Flatness Achieved: <.001"

Parallelism Achieved: .0001"

Comments

Only grinding one face. High volume, extensive tooling required.

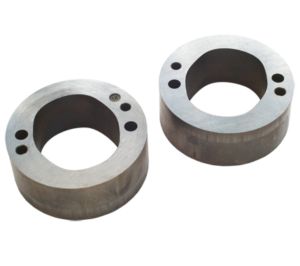

Machine: Stahli 705

Wheel: B64

Stock Removal: .010"

Parts Per Load: 96

Cycle Time: 2.5 mins

Rinsing Agent: Oil

Material: 1045 H.T. to 55 Rc

Previous Operation: Turned

Part Dimension: 1" O.D.

Tolerance: .0002"

Cpk Achieved: 1.67

Ra Achieved: 16

Flatness Achieved: <.0001"

Parallelism Achieved: .00001"

Machine: Stahli 1205

Wheel: D76

Stock Removal: .020"

Parts Per Load: 48

Cycle Time: 4.5 mins

Rinsing Agent: Oil

Material: Powdered Metal

Previous Operation: None

Part Dimension: 3" X 4"

Tolerance: .004"

Cpk Achieved: 12+

Ra Achieved: 20-30

Flatness Achieved: <.0002"

Parallelism Achieved: .00001"

Comments

Previous operation double disc grind then lap.

Machine: Stahli 1205

Wheel: D76

Stock Removal: .020"

Parts Per Load: 48

Cycle Time: 4.5 mins

Rinsing Agent: Oil

Material: Powdered Metal

Previous Operation: None

Part Dimension: 3" X 4"

Tolerance: .004"

Cpk Achieved: 12+

Ra Achieved: 20-30

Flatness Achieved: <.0002"

Parallelism Achieved: .0001"

Comments

Previous operation rough grind then finish grind, now achievable in one step process.

Machine: Stahli 705

Wheel: B64

Stock Removal: .015"

Parts Per Load: 572

Cycle Time: 3 mins

Rinsing Agent: Oil

Material: 1045 H.T. to 55 Rc

Previous Operation: Turned

Part Dimension: 400 O.D.

Tolerance: .0004"

Cpk Achieved: 1.67

Ra Achieved: 12

Flatness Achieved: <.000040"

Parallelism Achieved: .00004"

Comments

Only grinding one face. High Volume, extensive tooling required.

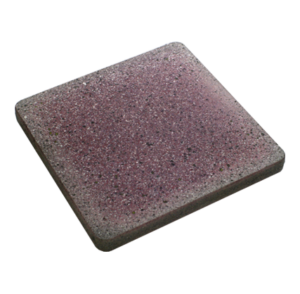

Machine: Stahli 705

Wheel: D76

Stock Removal: .030"

Parts Per Load: 24

Cycle Time: 10 mins

Rinsing Agent: Oil

Material: Ceramic

Previous Operation: None

Part Dimension: 4.5" X 4.5"

Tolerance: .00004" Flat

Cpk Achieved: 1.67

Ra Achieved: 16

Flatness Achieved: <.0002"

Parallelism Achieved: .0002"

Comments

Out of flat up to .010" per side incoming.

Machine: Stahli 1205

Wheel: D76

Stock Removal: .020"

Parts Per Load: 48

Cycle Time: 4.5 mins

Rinsing Agent: Oil

Material: Powdered Metal

Previous Operation: None

Part Dimension: 3" X 4"

Tolerance: .0002"

Cpk Achieved: 1.67

Ra Achieved: 16

Flatness Achieved: <.0002"

Parallelism Achieved: .0006"

Comments

Previous operation rough grind then finish grind, now achievable in one step process.

We're currently revamping our case studies for single side lapping. Check back soon or contact us for more info.

We're currently revamping our case studies for double side lapping. Check back soon or contact us for more info.

We would welcome the opportunity to quote any new projects or process samples of existing projects that you may have. Fill out the form to get in touch and see how you can put your problems in our laps!

Don’t hesitate to contact us for more information about our company or services